http://www.7mmvalkyrie.com

The 7mm Valkyrie AR is a wildcat hunting round being developed for the AR15. It is based on the 6.5x47 Lapua case with the shoulder pushed back to allow it to run in the ar15 at 2.295 oal and necked up to 7mm. Case trim length will be 1.596-1.60 and case capacity should be in the 42-43.5 grains of water.

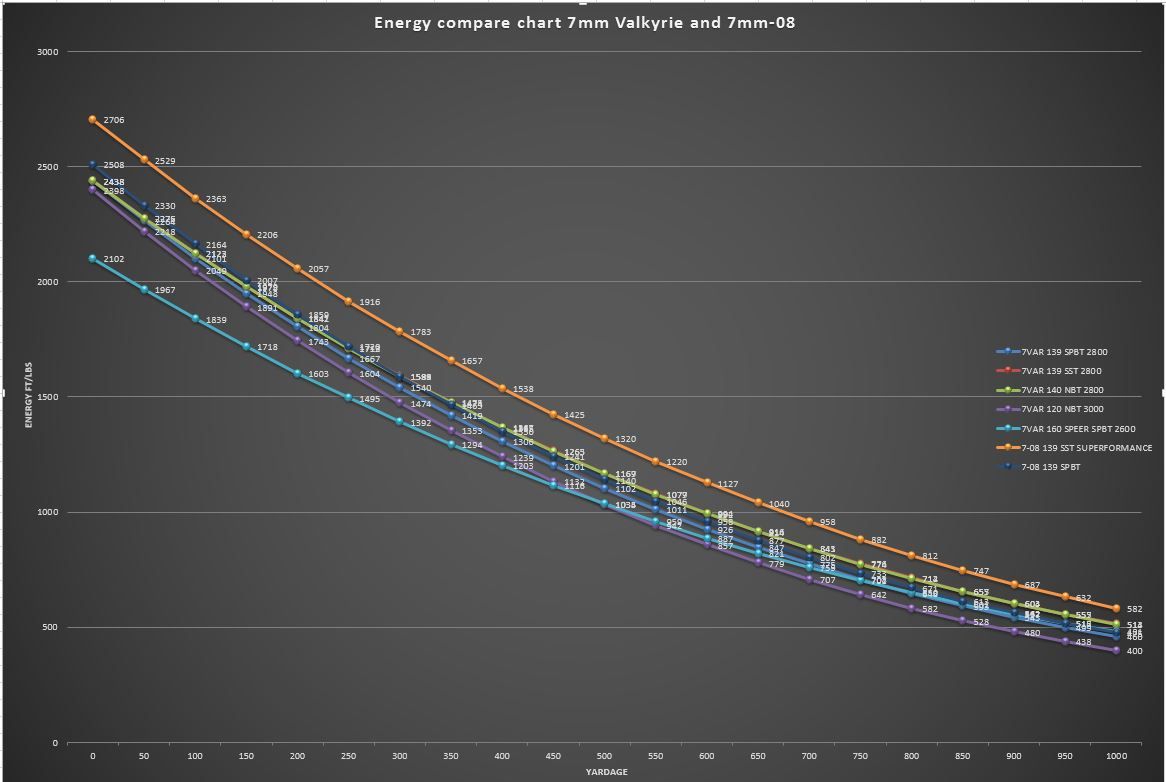

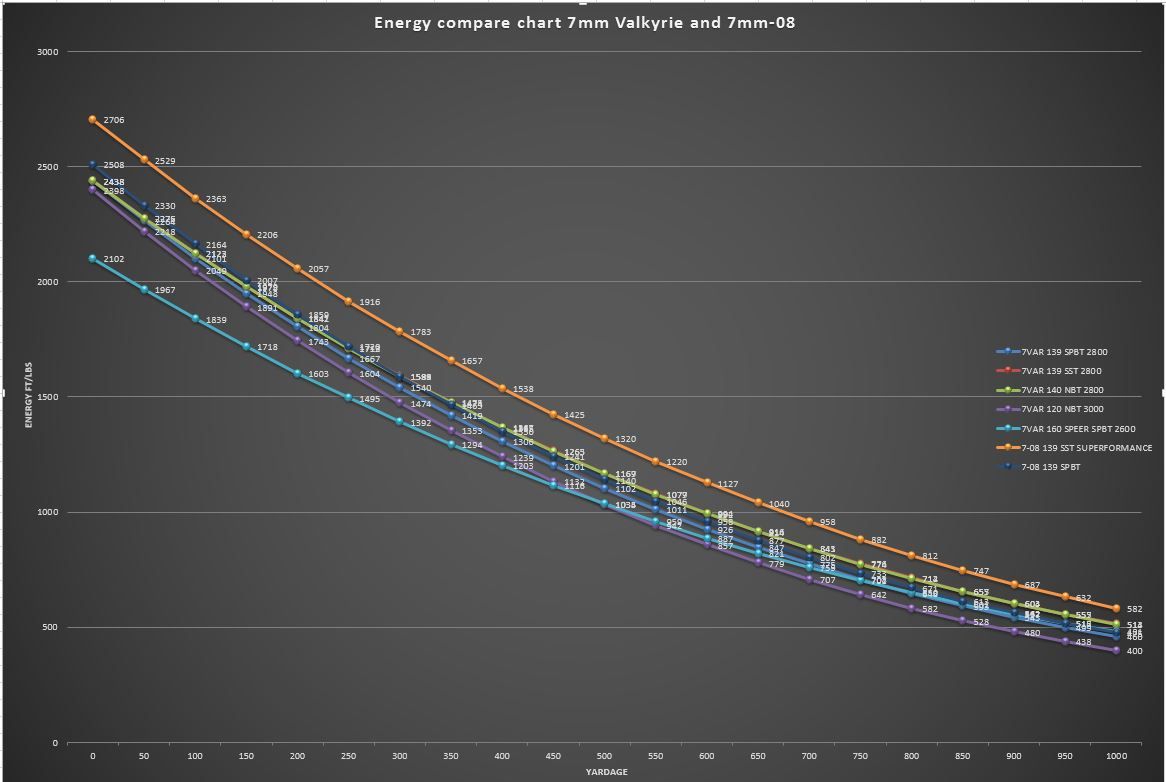

It is designed around the 140 class of bullets which should be pushed to 2700-2800 fps from a 24" barrel. Most 150 and 160 class will also be able to run in it with the 160 sierras being able to run at 2.25 oal so they will work perfectly in 300 black out mags. Estimates are for 2600 fps from the 160's. 120 class bullets should be in the 2900-3000 range and the 110's in the 3000-3100 range

.

The 7VAR With the 2.295 oal PRI 6.8 magazines work best allowing 7 rounds in a 10 round mag. The larger mags don't allow much more capacity because the magazine starts to swell.

The Valkyrie is a reloader only caliber for now. The case forming requires neck turning and reaming, neck thickness needs to be .012 - .0135. As stated 6.5x47 lapua brass is the best brass to make the cases from. It forms the easiest, lasts the longest, is small primer and handles the pressures the best. Also there is zero loss rate when forming.

6.5 creedmoor cases also work but the brass is softer and only lasts 2-4 firings on average. It also has a loss rate of 10% when forming from creases/folds in the neck/shoulder area. It does have the highest case capacity. Winchester 308 brass also works but you still have a 10% loss rate when forming. Any 308 based case can be used but case capacity suffers, work to make them increases so that is why they are not on the recommend list.

There will be 3 guys offering brass conversion for the 7 VAR, 270AR and the 257 Bobcat. Already processed brass will also be available in a limited capacity to start.

You can join in on the talks with us on our facebook group page https://www.facebook.com/groups/7mmVar/

Dies will be from Whidden gunworks with their competition micrometer seater die which is one of the best in the industry.

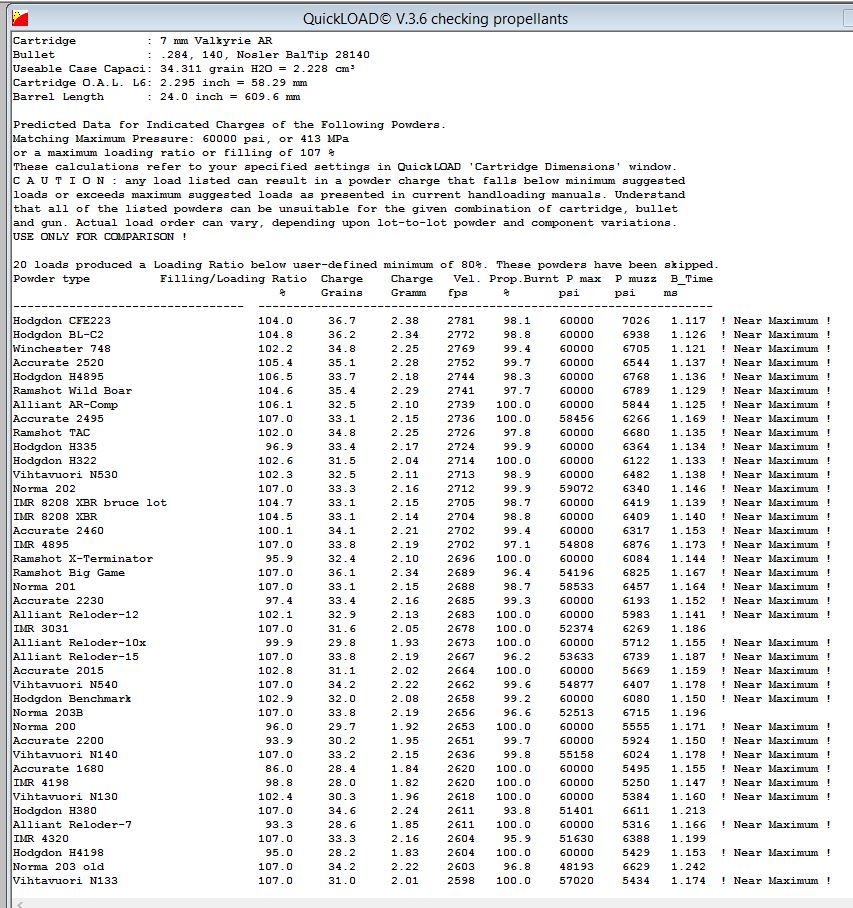

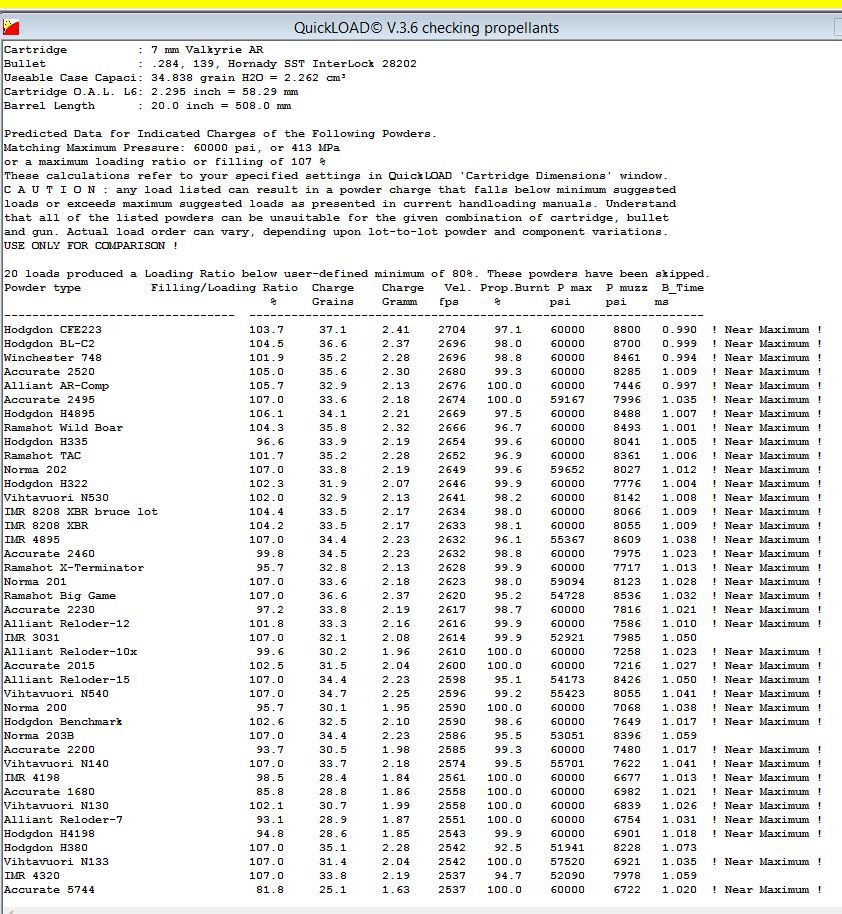

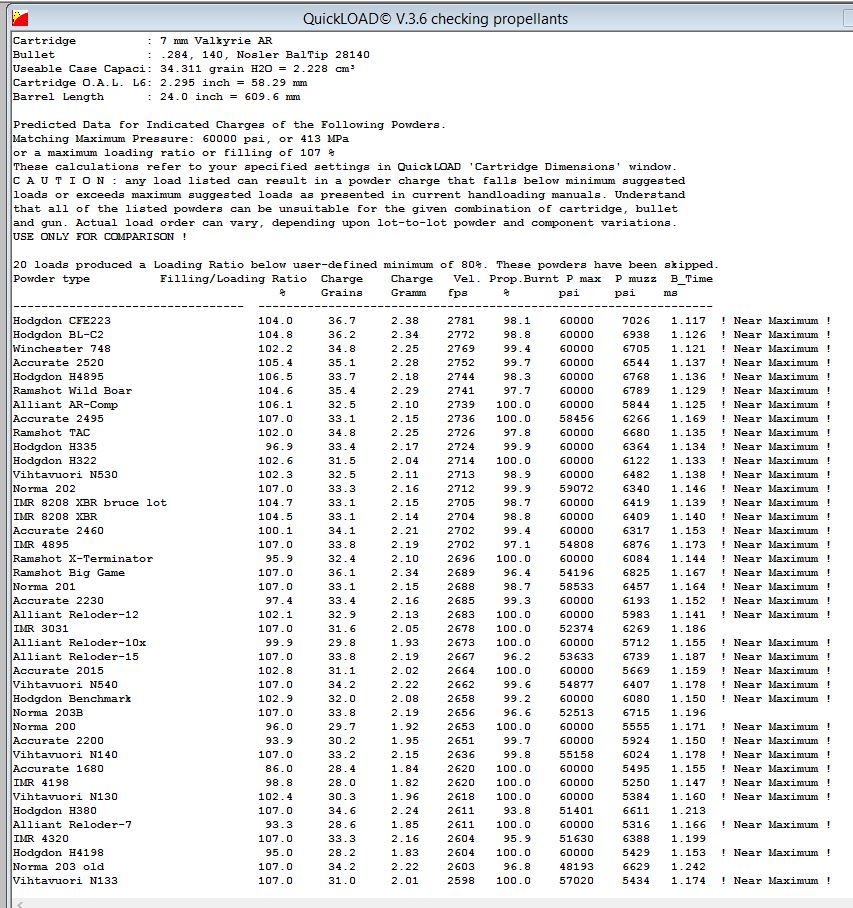

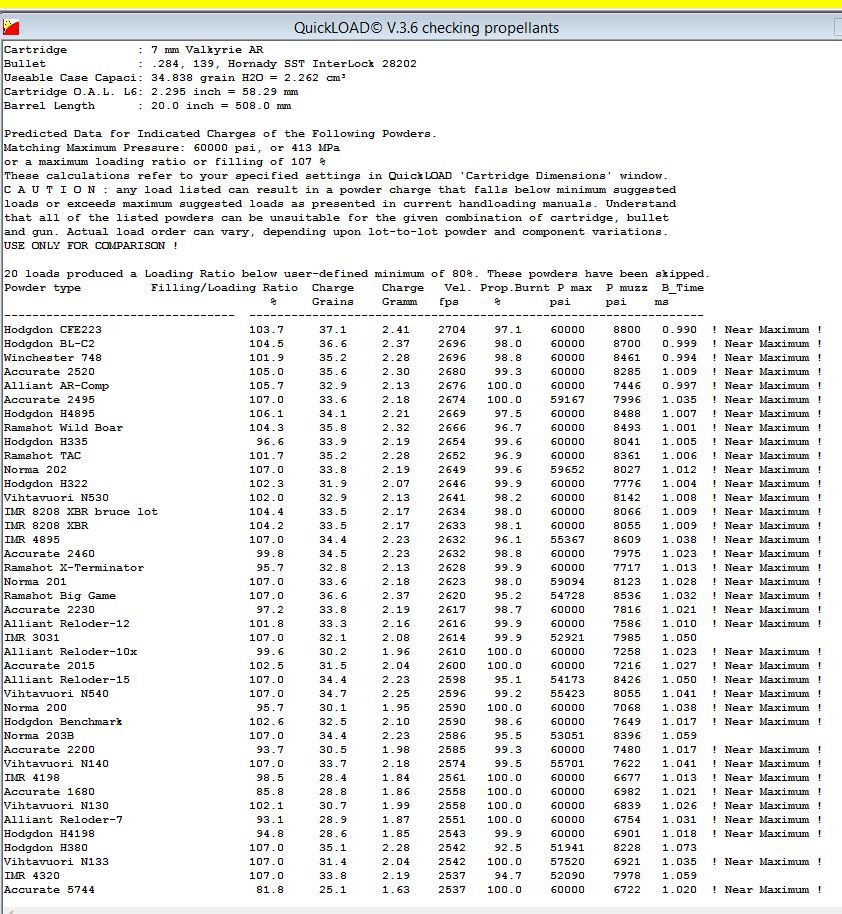

Some of the powders expected to work well with the Valkyrie are: CFE 223, Leverevolution, xbr 8208, H335, AA2520, Tac, Xterminator. Also r15 and arcomp might also work well also n530,n540 and n550 should be workable powders.

We are taking the community development route with this round. We have 15 founders and 10 of those are testers ready to test barrels from 16.5" to 26". Reamers will be due mid march with testing starting with a savage bolt gun 26" barrel. Then 5-8 weeks later the ar barrels should be done and come online for testing. Eisenach Arms is in on the development and will have a limited edition upper receiver with the Valkyrie logo.

7 mm Valkyrie tenetive time line

Jan 8th ordered reamers

March 10th Reamers due

March 15th Chamber first test barrel - 26" savage will also make 2 dillon trim dies and 3 forming dies before sending reamers to whidden.

March 16-19 Order dies -- payments for dies are due by april 1st 5-8 weeks to get dies from the 1st -- they make custom dies first 2 weeks of month.

April 3rd Tester's barrel payments due - tester barrel order date - (sooner if we can) or any founder that wants their barrel.

May 13th Dies will be done soon.

May 15th Tester barrels should be arriving soon

June 1st All testers should have barrels and we should be in full test mode.

June 15 - July 1 if all testing is good order rest of founder's group barrels - barrel payments due for final group.

August 1st will start taking orders for first group buy, will only be open for 2 weeks. want to place order by aug 15 so barrels can be in hands for hunting season.

Comparing the Valkyrie case to the 270AR case. I opted to push the shoulder back a little further so we could run all 140 class bullets at 2.295 and most 150 and 160 class bullets. It just gave more room to play. first is the 140 nosler bt next is the 120 nosler bt, then the 270ar case, 139sst all of them at 2.295. on the far right is a 270ar case just necked up and a 139sst seated. it has to be seated at 2.35 to keep the ogive out of the case.

I will be using the pressure trace system to collect pressure data during testing.

Here is estimated data, it should be close I used information gained with the 270AR and the 257 Bobcat to hopefully come up with some close estimations.

The 7mm Valkyrie AR is a wildcat hunting round being developed for the AR15. It is based on the 6.5x47 Lapua case with the shoulder pushed back to allow it to run in the ar15 at 2.295 oal and necked up to 7mm. Case trim length will be 1.596-1.60 and case capacity should be in the 42-43.5 grains of water.

It is designed around the 140 class of bullets which should be pushed to 2700-2800 fps from a 24" barrel. Most 150 and 160 class will also be able to run in it with the 160 sierras being able to run at 2.25 oal so they will work perfectly in 300 black out mags. Estimates are for 2600 fps from the 160's. 120 class bullets should be in the 2900-3000 range and the 110's in the 3000-3100 range

.

The 7VAR With the 2.295 oal PRI 6.8 magazines work best allowing 7 rounds in a 10 round mag. The larger mags don't allow much more capacity because the magazine starts to swell.

The Valkyrie is a reloader only caliber for now. The case forming requires neck turning and reaming, neck thickness needs to be .012 - .0135. As stated 6.5x47 lapua brass is the best brass to make the cases from. It forms the easiest, lasts the longest, is small primer and handles the pressures the best. Also there is zero loss rate when forming.

6.5 creedmoor cases also work but the brass is softer and only lasts 2-4 firings on average. It also has a loss rate of 10% when forming from creases/folds in the neck/shoulder area. It does have the highest case capacity. Winchester 308 brass also works but you still have a 10% loss rate when forming. Any 308 based case can be used but case capacity suffers, work to make them increases so that is why they are not on the recommend list.

There will be 3 guys offering brass conversion for the 7 VAR, 270AR and the 257 Bobcat. Already processed brass will also be available in a limited capacity to start.

You can join in on the talks with us on our facebook group page https://www.facebook.com/groups/7mmVar/

Dies will be from Whidden gunworks with their competition micrometer seater die which is one of the best in the industry.

Some of the powders expected to work well with the Valkyrie are: CFE 223, Leverevolution, xbr 8208, H335, AA2520, Tac, Xterminator. Also r15 and arcomp might also work well also n530,n540 and n550 should be workable powders.

We are taking the community development route with this round. We have 15 founders and 10 of those are testers ready to test barrels from 16.5" to 26". Reamers will be due mid march with testing starting with a savage bolt gun 26" barrel. Then 5-8 weeks later the ar barrels should be done and come online for testing. Eisenach Arms is in on the development and will have a limited edition upper receiver with the Valkyrie logo.

7 mm Valkyrie tenetive time line

Jan 8th ordered reamers

March 10th Reamers due

March 15th Chamber first test barrel - 26" savage will also make 2 dillon trim dies and 3 forming dies before sending reamers to whidden.

March 16-19 Order dies -- payments for dies are due by april 1st 5-8 weeks to get dies from the 1st -- they make custom dies first 2 weeks of month.

April 3rd Tester's barrel payments due - tester barrel order date - (sooner if we can) or any founder that wants their barrel.

May 13th Dies will be done soon.

May 15th Tester barrels should be arriving soon

June 1st All testers should have barrels and we should be in full test mode.

June 15 - July 1 if all testing is good order rest of founder's group barrels - barrel payments due for final group.

August 1st will start taking orders for first group buy, will only be open for 2 weeks. want to place order by aug 15 so barrels can be in hands for hunting season.

Comparing the Valkyrie case to the 270AR case. I opted to push the shoulder back a little further so we could run all 140 class bullets at 2.295 and most 150 and 160 class bullets. It just gave more room to play. first is the 140 nosler bt next is the 120 nosler bt, then the 270ar case, 139sst all of them at 2.295. on the far right is a 270ar case just necked up and a 139sst seated. it has to be seated at 2.35 to keep the ogive out of the case.

I will be using the pressure trace system to collect pressure data during testing.

Here is estimated data, it should be close I used information gained with the 270AR and the 257 Bobcat to hopefully come up with some close estimations.